-

Ex-MLB pitcher sleeping with family nanny guns down in-laws amid financial struggles - 30 mins ago

-

‘Miss Independent’ singer Kelly Clarkson says dating in spotlight is difficult - 39 mins ago

-

Merrill Kelly Trade Expected, Surging Red Sox Tabbed ‘Best Fit’ - 39 mins ago

-

Who is Jacob Misiorowski? Rookie All-Star Chats Pokémon, Card Collection - 41 mins ago

-

Target says it’s ending its Amazon and Walmart price matching policy after a 12-year run - 58 mins ago

-

Ex-MLB pitcher sleeping with family nanny guns down in-laws amid financial struggles - about 1 hour ago

-

Alabama, Kalen DeBoer Land Huge News Regarding Elite 2026 QB - about 1 hour ago

-

Fox News Entertainment Newsletter: ‘The Cosby Show’ star dead at 54, Christie Brinkley’s devastating moment - about 1 hour ago

-

College Football Stock Watch: Teams Joel Klatt Is Buying, Selling Stock in for 2025 - about 1 hour ago

-

L.A. Unified test scores rise above pre-pandemic levels. - 2 hours ago

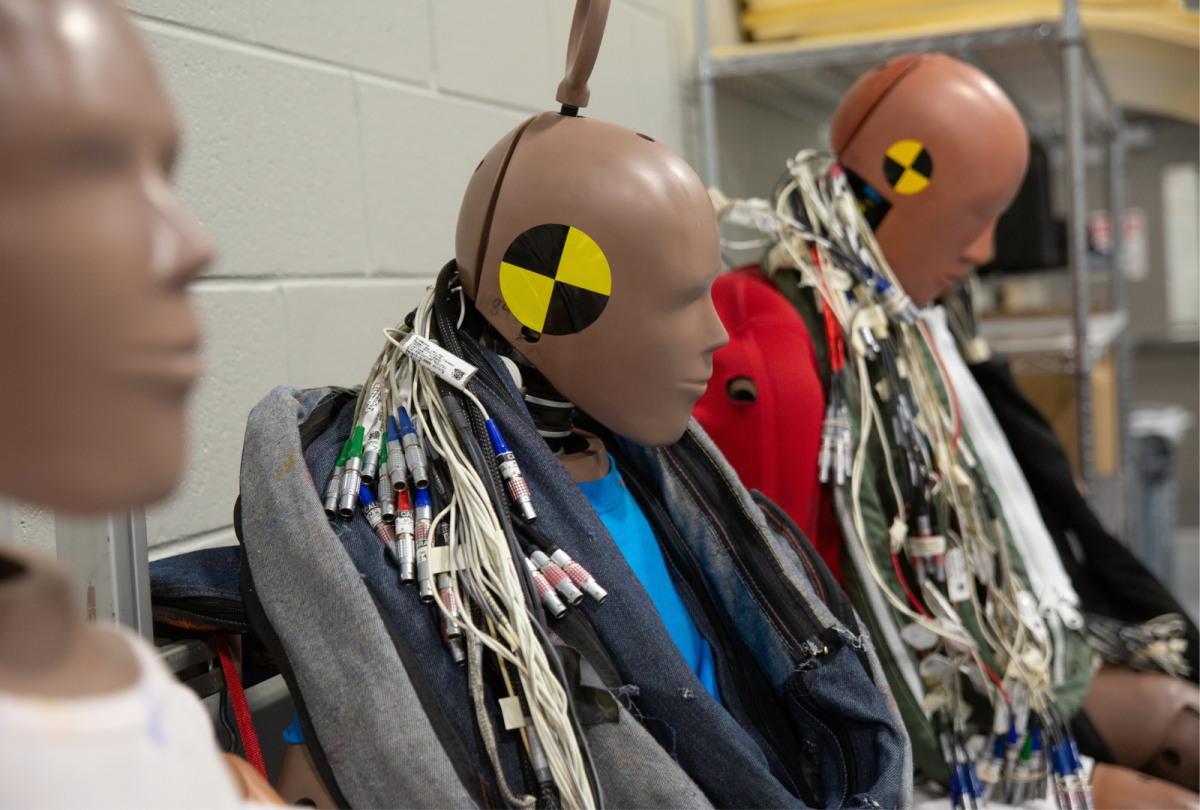

Automakers Still Need to Crash Test Cars Despite Advances in AI

Peering out a window at Torslanda Works, one of Volvo’s largest production facilities in Sweden, reveals a side lot filled with crashed cars. The automaker still conducts physical crash tests of vehicles despite artificial intelligence making it possible to conduct repeated tests under a wide variety of factors in rapid succession.

Volvo’s not alone. Almost every automaker crash tests its cars, even as sustainability has come into focus and technology has advanced. And they do it at various stages of development, ahead of the model coming to market and before the Insurance Institute for Highway Safety (IIHS) or Euro NCAP get their hands on it.

“While virtual crash testing has come a long way, physical crash tests remain a crucial complement. It allows us to directly evaluate how the car’s hardware performs in real-world scenarios. Even as our virtual models continue to improve, physical testing is needed to validate and refine them to ensure accuracy,” Lotta Jakobsson, senior technical specialist for injury prevention at Volvo Cars, told Newsweek.

At the automaker’s crash testing facility in Torslanda, a Volvo spokesperson told the audience, “To evolve car safety isn’t a wish. We bring that bold ambition into action, and we prove we reach there by relentless and rigorous testing in this crash lab. But as technology evolves, of course, so do we.”

Volvo Cars

Today, Volvo utilizes data from a car’s sensors in real time and computer simulations that include human body models (crash test dummies). They also reconstruct and analyze accidents that occur with their models, bringing some of them back to Volvo’s labs to study in detail the effects of physics on sheet metal, electronics and high-strength steel.

“When everyone else starts talking about collecting data on the road while the cars have been doing exactly that for more than 50 years, and most importantly, we have been analyzing that data and applying the knowledge and insight we gain into our product development to continue improve safety in every generation of all the cars,” the spokesperson said.

Volvo conducts 200-250 crash tests annually. A new model on a new platform, the spokesperson said, is crashed around 130-140 times alone. That’s physically. Virtually, Volvo conducts more than 80,0000 crashes annually on around 80 different vehicles. “We run multiple tests on the same car. You have to consider all different speeds, different sizes of occupants, and so forth. So it’s quite a wide matrix,” he said.

In May, Volvo initiated the first public three-car crash test in front of an assembled crowd at the company’s Stars Safety Center facility in Torslanda. The three Volvo EX90 electric SUVs performed “within tolerances,” a spokesperson said. While one vehicle was parked horizontally, another hit its driver’s side cabin at speed. In quick succession, another EX90 was propelled toward the parked SUV, and utilizing its accident avoidance technology, it was able to come to a last-second stop, barely kissing the bumper of the vehicle ahead.

Last year, Mercedes-Benz celebrated the world’s first frontal offset crash between two electric vehicles. The parameters of the crash were different than the crash Volvo conducted. It demonstrated the effects of an EQA and an EQS SUV colliding head-on with a 50 percent overlap while each traveled at 56 kilometers per hour.

“Crash test simulations are an integral part of our vehicle development. We conduct around 15,000 simulations per model series and 150 real crash tests before the development is completed,” Prof. Dr. Paul Dick, director of vehicle safety at Mercedes-Benz Cars & Vans, told Newsweek.

“Even though our simulations and calculations are excellent and can predict the outcome of a crash test quite precisely, we still have to validate the results in hardware. This is not only due to legal requirements, but also enables us to ensure that complex protection systems, such as the deactivation of high-voltage components, the protection of the passenger cell and the battery housing, also provide protection in extreme situations. In doing so, we go beyond legal requirements and those of the rating agencies… Our goal is clear when we develop a new vehicle: We always aim to build the safest vehicle in its class – that is our Mercedes-Benz Engineering Excellence.”

Mercedes-Benz

Nissan’s Safety Advancement Lab is part of a $40 million facility that was built in 2021 to expand the company’s research and development operations in North America. Each year, the lab’s engineers put around 400 vehicles through physical crash tests.

“Most crash test modes are able to be conducted in a digital environment using computer-aided engineering (CAE). CAE is conducted to help develop and refine the design of systems and components before a vehicle model is physically built. Once prototype or pre-production vehicles are built then physical crash testing is conducted. There is an overall high level of correlation between the digital CAE models and physical tests but there are certain limitations to CAE that make the physical testing valuable and key to an overall assessment,” Mike Bristol, Nissan’s director of engineering safety, design and performance, told Newsweek.

Three Nissan SUVs, Murano, Pathfinder and Armada, earned the Top Safety Pick+ rating from the Insurance Institute for Highway Safety this year. That is IIHS’s highest mark.

Those models protect drivers and passengers in the real world with Nissan’s Safety Shield 360 suite of six safety-centric advanced driver-assistance features. Those features require validation long before they reach customers.

Nissan

“Individual components and systems are designed and tested to meet individual criteria but ultimately they have to work together as a whole vehicle level assembly to perform in full vehicle crash tests. These crash tests give us the final validation to confirm our vehicles are providing protection for our customers when they need it most,” Bristol said.

Source link